Posted 16 September 2019

Fibre Optic - feel the need for speed?

As the cost of fibre optic cabling continues to fall it’s now a viable option for an increasing number of telecommunications and data networking applications, and as a result, fibre optics are now in widespread use.

Where copper cabling uses electricity to transmit signals from one end to another, fibre optics use light pulses to achieve the same result. Light passes through the cable, bouncing off the cladding until it reaches the other end – a process called total internal reflection. This method of data transfer offers a number of advantages over copper data cabling:

Speed - fibre optic cables are able to transmit data much faster than LAN copper data cables.

Lower attenuation (signal loss) over greater distances - Copper cables may require a booster to cover long distances while singlemode fibre can reliably go thousands of metres without amplification.

No crosstalk - Copper is prone to electromagnetic interference that can scramble data; not a problem with fibre because the signal is sent as light instead of current.

Security - fibre does not radiate EMI signals, making it difficult to intercept.

Futureproofing - The standard transmission speed for fibre in data centres is rapidly becoming 40 Gbps. As data loads have increased in our information-hungry world, fibre optic cable is able to keep up with current and future demands.

Construction

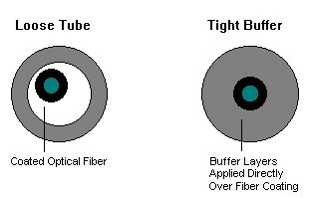

A fibre optic cable is made up of a pure glass core surrounded by a reflective cladding to retain the signal. The fibre cores can either be housed in a gel filled loose tube or each fibre can be tight buffered in its own mini jacket allowing the core to be directly terminated onto a connector. The cable may contain various water blocking layer and aramid strength members under the outer jacket. Corrugated steel tape or steel wire armour can also be applied to provide mechanical protection.

Fibre Sizes

The size of the optical fibre is commonly referred to by the outer diameter of its core, cladding and coating. Example: 50/125/250 indicates a fibre with a core of 50 microns, cladding of 125 microns, and a coating of 250 microns. The coating is normally removed when joining or connecting fibres. A micron (µm) is equal to one-millionth of a meter. 25 microns are equal to 0.0025 cm. A fibre core is similar to the thickness of a human hair.

Singlemode and Multimode

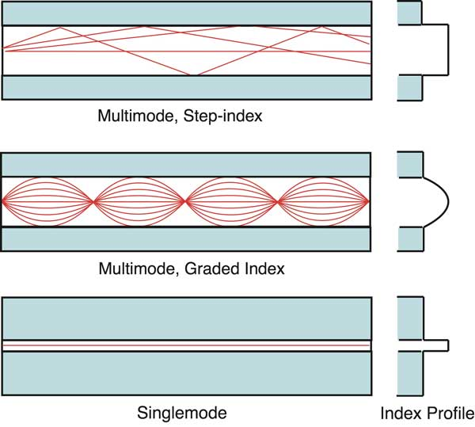

There are two basic types of optical cable used for data and communications, singlemode and multimode. The principle differences are core size and the data performance. Fibre is measured by its core diameter (9, 50 or 62.5µm) and the cladding diameter (125µm).

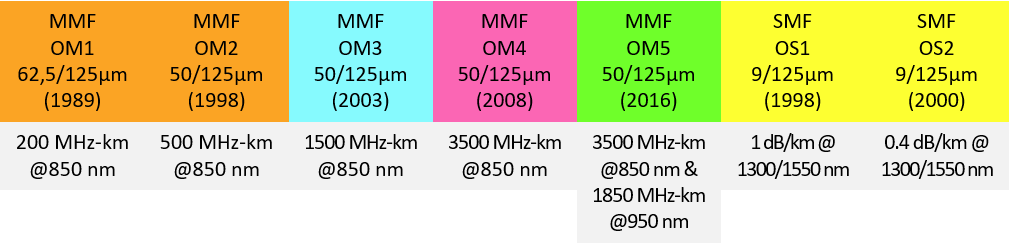

ISO 11801 provides the OS/OM coding system for identifying fibre types. As you will see from the table below there are four different performance levels available of 50/125 multimode fibre so specifying OM3 is far safer than simply relying on the fibre size as a description.

Singlemode fibre involves much less internal reflection as light passes along it, which in turn reduces attenuation and allows for much higher speed data transfer over long distances. By contrast, multimode fibre cabling dramatically increases the amount of reflection, which in turn causes higher dispersion and attenuation rates, and thus increases bandwidth delivery over shorter distances. Singlemode is typically used for long-distance signal transmission, while applications requiring volume of data to be sent over a shorter run tend to use multimode fibre optic cabling.

Singlemode fibre involves much less internal reflection as light passes along it, which in turn reduces attenuation and allows for much higher speed data transfer over long distances. By contrast, multimode fibre cabling dramatically increases the amount of reflection, which in turn causes higher dispersion and attenuation rates, and thus increases bandwidth delivery over shorter distances. Singlemode is typically used for long-distance signal transmission, while applications requiring volume of data to be sent over a shorter run tend to use multimode fibre optic cabling.Loose Tube or Tight Buffered?

Loose-tube cables are generally better suited for outdoor applications. The gel filled loose tube provides water resistance and protects the fragile fibres from external stresses. Loose tube cables require termination by splicing.

Tight-buffered fibres are covered in a polymer jacket allowing direct termination onto standard connectors without the need for pig-tail splicing. Many tight buffered cables (but not all!) are classed as internal/external allowing them to be routed inside building as and across campus to other buildings.

Attenuation within an optical fibre

Although fibre optic cables can offer superior performance to copper data cables they are still subject to attenuation loss. This can be caused by:

- Loss associated with the impurities - There will always be some level of impurity in the core of the optical fibre. This will cause some absorption of the light within the fibre. One major impurity is water that remains in the glass fibre.

- Loss associated with the cladding - When light reflects off the interface between the cladding and the core, the light will actually travel into the core a small distance before being reflected back. This process is one of the main contributors to the overall attenuation loss of signal.

- Loss associated with the wavelength - The level of signal attenuation depends the signal wavelength. At certain wavelengths attenuation can increase as a result of impurities in the glass.

As with all types of cabling

-

particularly data and communications cable - there’s a vast range of choice

when it comes to choosing the most appropriate product for

your

intended uses and environments. Construction materials

and core configurations will all play an important part

in defining

which type of product is best for your needs, as they’ll directly influence

factors such as data transfer speeds, bandwidth, reliability and longevity in different

applications.

You’ll also need to be mindful of connectivity requirements.

Installing fibre could be easier than you think! You could consider a pre-terminated option.

Pre-terminating allows

a fibre optic network to be installed in a fraction of the time taken by

conventional on-site direct termination or fusion splicing. It requires no

special installation skills or equipment, and can therefore be installed by

non-specialist personnel, vastly reducing the installation cost.

Pre-terminated fibre cables from FS

Cables are UK manufactured and tested, all lengths are

fully traceable with a test certificate included with every assembly.

We can

pre-terminate your fibre cables for your particular application in your choice

of connector types of LC (snap-in connectors that are best suited for

high-density connections), ST (straight tip connectors which use a twist on and

off connector) or SC (push-pull connectors and are the most common requirement

for fibre connections in the Datacom sector as well as domestic fibre optic

connections) if required.

Our fibre cable assemblies can be ordered and

cut to any length required and come in 2 Core (duplex), 4, 8, 12, 16 and 24

core counts, allowing for true versatility in custom applications. All our

pre-terminated fibre comes with a pulling eye and sock to protect the cables

during working and installation.

For further information on fibre optic

cable technologies in general, or to discuss the potential applications of any

specific product, please contact our

expert technical sales team for advice and assistance.

01727 840841 sales@fscables.com